See All: Cheese Making

Watch How To Do This Here…

YES! You can make cheese at home. Take our FREE 4-Part video training series to simplify cheesemaking for everyone. No waste. No overwhelm. No missing steps. You can make delicious, healthy cheese, even if you only have access to grocery store milk and regular kitchen equipment…

Click Here To Watch Step By Step Now

“I’ve just finished setting up my cheese aging room here in Portland, Oregon, and I’ve been hearing a lot about how crucial proper ventilation is for the cheese aging process. I’d love to understand more about this. Could you explain the role of proper ventilation in cheese aging rooms and why it’s so important?” Cheers, Patrick, Portland, USA.

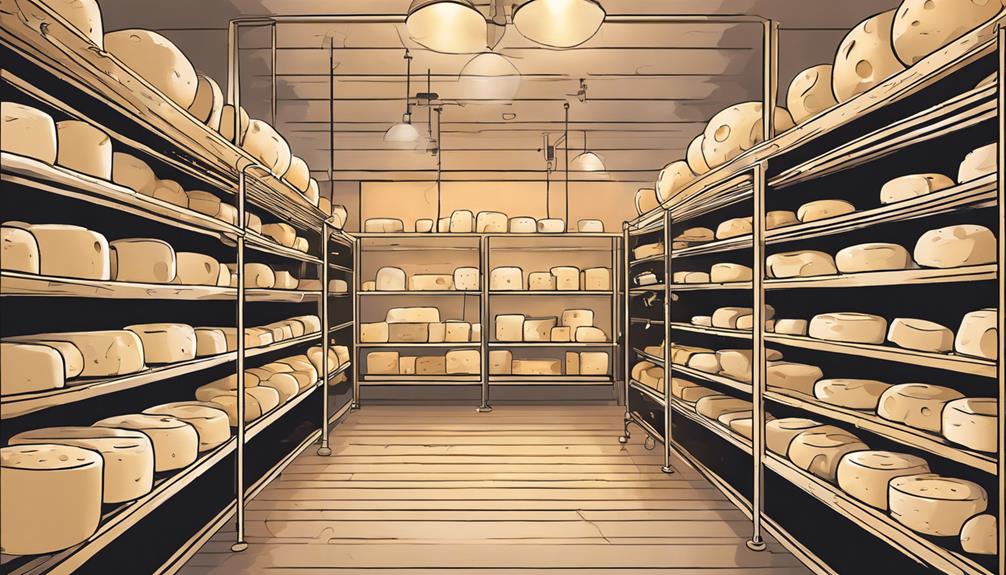

The Role of Proper Ventilation in Cheese Aging Rooms

Hey Patrick, congrats on setting up your cheese aging room! Proper ventilation is indeed a pivotal element to get right. Let’s dive into the whys and hows of good ventilation in cheese aging rooms.

The Basics of Cheese Aging

Cheese aging, or affinage, is a delicate process that transforms the texture and flavor of cheese over time. It involves a series of biochemical reactions, guided by factors like temperature, humidity, and, of course, air quality. Ventilation primarily affects how mold and bacteria develop and interact with the cheese.

Why Ventilation Matters

Proper ventilation controls the environment within the aging room. Here’s a breakdown of why it’s so essential:

- Maintaining Optimal Humidity Levels: Proper airflow helps regulate humidity. Too much moisture can lead to unwanted mold growth, while too little can cause the cheese to dry out and form cracks. Consistent humidity levels ensure the cheese retains moisture for the perfect texture.

- Preventing Unwanted Mold and Bacteria: With adequate ventilation, you minimize the risk of stagnant air, which can be a breeding ground for harmful bacteria and molds that compromise the quality of your cheese.

- Enhancing Flavor and Texture: Ventilation influences the biochemical processes responsible for the development of flavor and texture. Proper air circulation aids in the optimal development of beneficial molds and bacteria.

- Consistency Across Batches: An evenly ventilated room ensures that every batch of cheese ages uniformly. This consistency is crucial for product quality and customer satisfaction.

- Removal of By-products: Ventilation helps in the removal of unwanted smells and gases, such as ammonium, that can affect the taste and aroma of the cheese.

How to Achieve Proper Ventilation

Now that we’ve established the importance let’s look at how you can achieve it:

- Design and Layout: The physical arrangement of your aging room can impact air circulation. Stagger shelving and use perforated materials where possible to allow airflow around each cheese wheel.

- Fans and Vents: Use fans to circulate the air and strategically placed vents to introduce fresh air and expel stale air. Ensure fans are not directly blowing onto the cheese, as this can cause uneven aging.

- Humidifiers and Dehumidifiers: These devices work in tandem with your ventilation system to keep humidity at the optimal level (usually around 85-95% for most cheeses).

- Monitoring Systems: Install hygrometers and thermometers to constantly monitor the environment. Advanced systems can even alert you via smartphone apps about any changes that need to be made.

- Regular Maintenance: Ensure that all ventilation systems are clean and functioning properly. Filters should be replaced regularly to prevent clogging and inefficiency.

Common Mistakes and How to Avoid Them

It’s easy to overlook some aspects of ventilation, especially when you’re focused on other facets of cheese making. Here are a few pitfalls to avoid:

- Overloading the Aging Room: Too much cheese in one area can restrict airflow. Ensure there’s enough space for air to circulate freely around each piece.

- Ignoring Seasonal Changes: Ambient air quality can change with the seasons. Adjust your ventilation accordingly to maintain consistency throughout the year.

- Vent Placement: Placing vents directly above cheese can cause condensation to form on the cheese surface, which is not ideal. Position vents in a way that promotes indirect airflow.

- Lack of Backup Systems: Power outages can disrupt your ventilation system. Having a backup generator can save your batch during unforeseen events.

A Real-World Example: Époisses

One classic example of the role of ventilation is with the French cheese Époisses. This cheese requires high humidity and proper airflow to develop its famed washed rind. Without proper ventilation, the rind can become overly moist, encouraging the growth of unwanted molds and resulting in a poor texture and flavor.

Ventilation Types: Natural vs. Mechanical

Ventilation can be achieved through natural or mechanical means. Here’s a quick comparison:

Natural Ventilation

Uses natural air movement through strategically placed vents and windows. It’s cost-effective but harder to control, making it less ideal for commercial or large-scale operations.

Mechanical Ventilation

Involves the use of fans, ducts, and HVAC systems. While more expensive, it provides greater control over air quality, making it easier to maintain consistent conditions. This is generally preferred for serious cheese makers like yourself, Patrick.

Special Considerations for Different Cheeses

Different types of cheeses require different aging environments. For example:

- Blue Cheeses: Require cooler temperatures and more humid conditions, coupled with good ventilation to disperse the strong ammonia smell.

- Hard Cheeses (like Parmesan): Prefer slightly drier conditions and steady airflow to ensure slow and even moisture loss.

- Soft Cheeses: Need a higher humidity and gentle air movement to prevent drying out, allowing the rind to develop properly.

Tools and Equipment

To maintain proper ventilation, specific tools and equipment can be invaluable:

- Inline Fans: Effective for moving air through ducts and are quieter than traditional fans.

- Air Purifiers: Help remove contaminants from the air, ensuring a cleaner environment for aging cheese.

- Custom Shelving: Perforated racks allow better airflow around each cheese wheel.

Monitoring for Consistency

Once you’ve set up your ventilation system, it’s important to continually monitor its effectiveness. This will ensure that your cheese aging room remains in optimal condition:

- Temperature and Humidity Loggers: Use data loggers to track these variables over time, ensuring they stay within desired ranges.

- Regular Inspections: Physically examine the cheese for signs of improper aging such as unusual mold growth or inconsistent texture.

- Adjustments Based on Observations: Make slight tweaks based on your regular inspections. For instance, if you notice excessive mold, consider increasing ventilation or adjusting humidity.

Final Thoughts…

Patrick, I hope this gives you a clear understanding of why proper ventilation is so important in your cheese aging room. By carefully controlling airflow, you ensure that each cheese develops its full potential in flavor and texture. Thanks for reaching out with such a great question, and happy cheesemaking!

Return To: Cheese Making

Free Step By Step Cheese Making Videos…

YES! You can make cheese at home. Take our FREE 4-Part video training series to simplify cheesemaking for everyone. No waste. No overwhelm. No missing steps. You can make delicious, healthy cheese, even if you only have access to grocery store milk and regular kitchen equipment…